Honeywell IAQPoint2 (Discontinued)

IAQPoint2™ puts money in your pocket and fresh air comfort into your building by using demand-controlled ventilation and triple monitoring (CO2 or VOCs, Temperature and Humidity). *Although these products are no longer available for sale, they are still being supported by Technical Services and Support.

List of Benefits

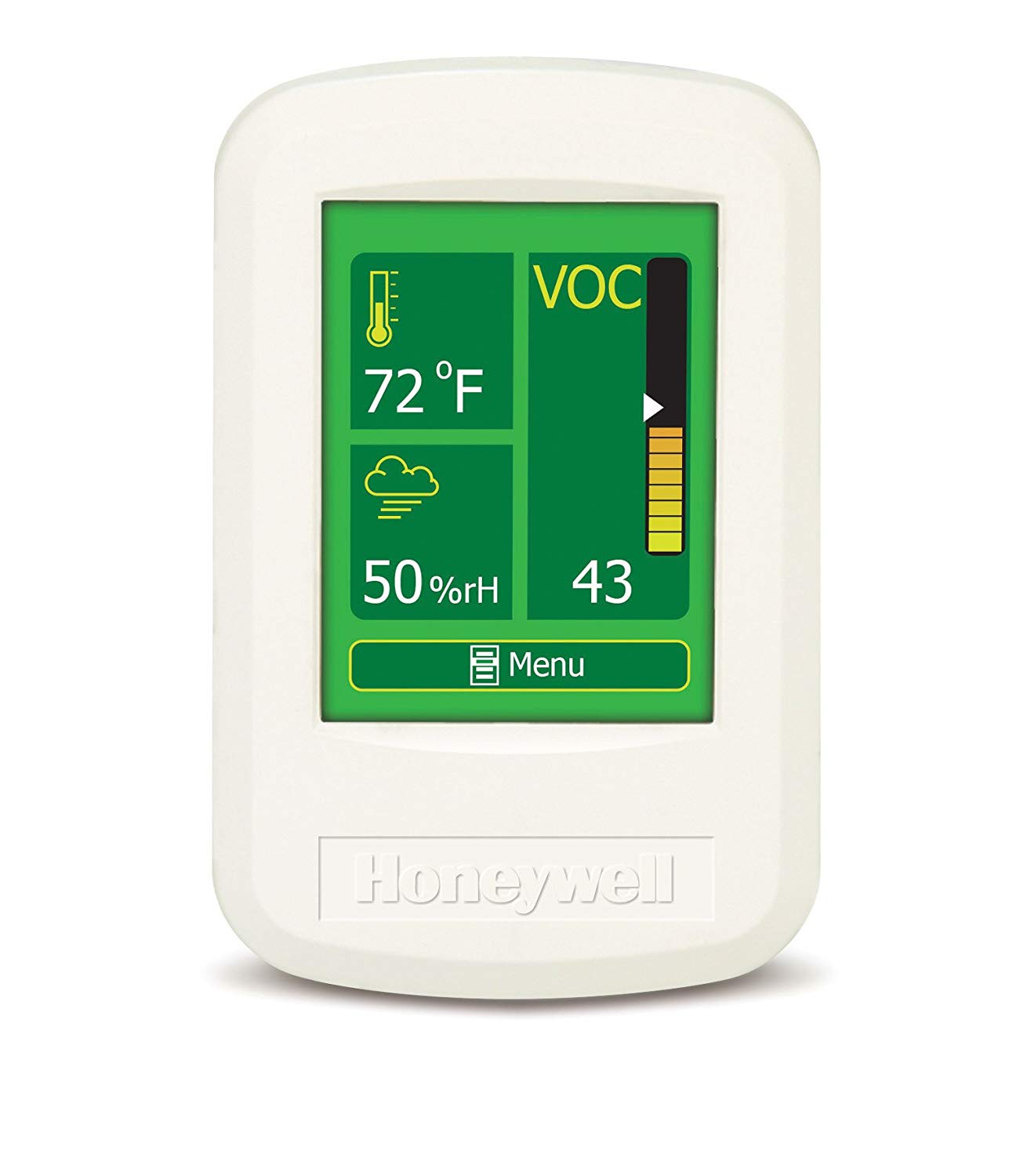

- User-Friendly Touchscreen Operation

- Menu driven, customizable, easy-to-navigate display

- Large VGA screen with easy-to-read graphical display

- Simple wall or duct-mount

- Multi-analog or digital (BACnet, Modbus, LonWorks) options

- DC and AC power; fits standard junction box

- 15 year sensor life with automatic self-calibration

- Adjustable set-points and optional relay for local fan activation

- 3-in-1 Monitoring

- Choose reliable CO2 or VOC sensing technologies

- Optimize room comfort through temperature control

- Integrates seamlessly with Building Automation Systems (BAS) via

- BACnet, Modbus, and LonWorks or 4-20mA

- Green Attributes – Obtain LEED credits

- Meet ASHRAE 62.1 standard

- Low power consumption and ‘sleep mode’ feature

- Optimize HVAC use and extend life of components

WHY MONITOR CARBON DIOXIDE?

High levels of CO2 can cause drowsiness and create an inefficient work environment for building occupants. To combat this problem, building managers may run the ventilation system continuously, but this is an inefficient, costly practice. With AQPoint2 in place, the ventilation system runs only as needed, cutting operational costs. Digital communications (BACnet, Modbus or LonWorks) connects to a BAS, adding intelligence and control. These advantages can boost building performance and profitability.

WHY MONITOR VOLATILE ORGANIC COMPOUNDS?

Increasingly, studies show a connection between the presence of VOCs (volatile organic compounds) and adverse health effects. Commercial, educational and government buildings contain VOCs by the thousands, such as:

- Organic odors, aerosols, disinfectants, cleansers (washrooms, kitchens)

- Paints, waxes, cleaning supplies, pesticides ( janitorial closets)

- Copiers, printers, correction fluids, adhesives, permanent markers, photographic solutions (copier/printing rooms)

- Fuel cans, solvents, preservatives, automotive and vehicle products (warehouses, shipping areas)

- Formaldehyde carpets (offices and office areas)

Override feature – Reset demand control ventilation settings based on room occupancy (e.g. during off-peak hours).

Temp/rH sensor – Adjust room temperature at the touch of a button; eliminate extra IAQ devices.

Calibration Port – Connect calibration tube for fast, accurate bump test; calibrate IAQPoint2 without opening the casing.

CO2 or VOC sensor – Monitor gas concentration readings to drive demand-controlled ventilation; achieve savings and comfort by avoiding over or under-ventilation.

USB Port – Update display graphics with logo and contact information; allow future uploads of product enhancements.

THE TOUCHSCREEN DIFFERENCE

IAQPoint2’s unique, patented touchscreen monitor brings leap-forward technology right to your fingertips, with benefits that extend from simplified installation and commissioning to user operation. You can set password levels and protect from tampering; configure fan activation set-points; select screen content, engineering units and language. You get control.

| Specification | Detail Description |

|---|---|

| IAQPoint2 with CO2 Sensor | |

| Gas | CO2 |

| Detection Method | Non-dispersive infrared (NDIR) with ABC automatic background calibration algorithm |

| Range | 0-2,000 ppm 0-5,000 ppm |

| Accuracy* | ±30 ppm +3% of reading @ 25°C for 0-2000 ppm ±30 ppm +5% of reading @ 25°C from 2000 to 5000ppm |

| Response Time | T90 < 60 seconds |

| Calibration | No Calibration Required |

| IAQPoint2 with VOC Sensor | |

| Gas | Voltile Organic Compounds (VOC's) |

| Detection Method | Metal oxide semiconductor (MOS) |

| Range | 0-100 (400-2,000 ppm CO2 Equivalent) |

| Response Time | T90 < 60 seconds |

| Calibration | No Calibration Required |

| Temperature Sensor | |

| Detection Method | Band Gap |

| Accuracy | ±0.5°C at 25°C and 50% rH |

| Humidity Sensor | |

| Detection Method | Capacitive Type |

| Range | 0-95% rH |

| Accuracy | ±5% at 25°C and 50% rH |

| Outputs | |

| Analog | 4-20 mA, 2-10 VDC fixed |

| Digital | Modbus RTU, BACnet MS/TP, BTL listed, LonWorks, LonMark certified |

| Relay | 3 Amps, 250 VAC resistive, and 30 VDC SPDT; Field configurable set point &hysteresis |

| Override | Selectable on Display Units |

| Mounting Options | |

| Wall Mount | IP22 |

| Duct Mount | IP54 |

| System Operation | |

| Temperature | 32° to 122°F (0° to 50°C); 32° to 104°F (0°to 40°C) for VOC Wall mount configurations |

| Humidity | 0 to 95% rH, Non-condensing |

| Power In | 20 to 30 VAC, 18 to 28 VDC |

| Consumption | 200 mA @ 24 VDC |

| Dimensions | 3.0 (w) x 4.6 (h) x 1.5 (d) in (11.8 x 7.7 x 3.7cm) |

| Weight | 0.44 lbs (.20 kg) |

| Enclosure | ABS |

| Display | TFT, Multicolor graphical touch screen display, 1.9 (w) x 2.6 (h) in (4.9 x 6.5 cm) (Optional with Analog units) |

| Languages English, French for first release | |

| Certifications | |

| US | ANSI/UL 61010-1 |

| Canada | CAN/CSA C22.2 No. 61010-1 |

| Europe | CE |

| Warranty | 1 year |

| *Note | Allow an additional ±2% of reading for calibration gas cylinder. With ABC enabled, allow 3 weeks for stabilization |

20190122-Honeywell-IAQPoint2-Brochure.pdf 160.75 KB

Manual - Current versions

20181129-Honeywell-IAQPoint2-Manual.pdf 2.9 MB

Specification Sheet

20181129-Honeywell-AQPoint2-SpecSheet.pdf 108.33 KB