D-Guard S (Discontinued)

*Although these products are no longer available for sale, they are still being supported by Technical Services and Support.

GasTech Australia's latest series of gas detectors: The Digital Guard (D-GuardTM). This new style of gas detector uses an advanced processor and program logic, making the choice of a reliable detector simple.

Our engineers have developed high end electronics and a program that monitors the sensor’s outputs and is tailored to and pre-programmed to many different gas types. The program and electronics process the sensor’s output trends and calculates accurate and stable readings which are displayed on the permanently backlit graphic display. This is transmitted back to the processor using the industry standard 4-20mA.

Mechanical design: One card to suit all applications is the philosophy. Many of our customers are in remote locations around the world and holding stock for all the different kinds of detectors and ranges that they have on site is expensive and difficult to manage. In the D-GuardTM design this card had to be easily configured for the different gasses, ranges, sensors styles and must have enough program memory to hold the logic for each type of gas. Our engineers were able to achieve all this, with enough resources still avaliable to implement many future features. Each card will be simple to upgrade as needs change.

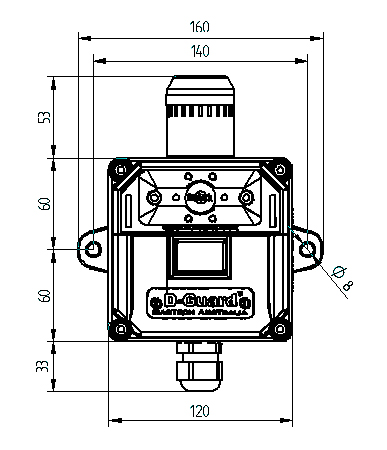

Housing is an IP 66 316 stainless steel filled anti static Nylon, which is UV stable. The design of the housing was designed to meet the most challenging conditions encountered in off shore oil rigs.

End-User Features

No tool calibration or set up.

No screwdrivers, No meters, no special programming tools required to calibrate.

Backlit display.

This feature is not available on most loop-powered devices due to high power consumption but it is one of the most requested features, due to operations at night or in dark areas. Our engineers used the latest low power components leaving sufficient resources to implement a back light.

No alarms during calibration.

This is probably one of the most useful features of this system. Once you open the calibration door the D-GuardTM locks the output signal at zero gas reading until the calibration process is finished. Our engineers have implemented a fail-safe logic to maintain constant monitoring. There is also an Isolate switch, which will permanently isolate all signals and alarms until the operator reactivates the unit.

Key Features

- Zero stability logic

- One man calibration

- Non intrusive calibration

- Graphical backlit display

- No alarm calibration

- Simple user options

- One board does all

- No tool calibration

- Isolate feature

- Intrinsically safe

- Fully programmable processor control

- High impact non-static housing

- Water resistant IP 66 design

- Two year warranty (**)

** 1year on all other sensors

Part Number

- 65-1012-xxx (xxx is gas type, eg. CO or H2S)

Gases Detected

| Ammonia (NH3) | 0 to 100 ppm in 1 ppm increments |

| Carbon Monoxide (CO) | 0 to 100 ppm in 1 ppm increments |

| Chlorine (CL2) | 0 to 10 ppm in 0.1 ppm increments |

| Hydrogen (H2) | 0 to 100 ppm in 0.5 ppm increments |

| Hydrogen Cyanide (HCN) | 0 to 50 ppm in 1 ppm increments |

| Hydrogen Sulfide (H2S) | 0 to 200 ppm in 1 ppm increments |

| Hydrogen Cloride (HCL) | 0 to 200 ppm in 1 ppm increments |

| Nitric Oxide (NO) | 0 to 100 ppm in 1 ppm increments |

| Nitrogen Dioxide (NO2) | 0 to 10 ppm in 0.1 ppm increments |

| Phosphine (PH3) | 0 to 1 ppm in 0.01 ppm increments |

| Sulfur Dioxide (SO2) | 0 to 10 ppm in 0.1 ppm increments |

| Ethylene Oxide (ETO) | 0 to 20 ppm in 0.1 ppm increments |

| Ozone (O3) | 0 to 2 ppm in 0.01 ppm increments |

| Oxygen (O2) | 0 to 25% in 0.1 %Vol increments |

*Increased sensors and detection range available on request.